- Information

- AI Chat

Case Study Toyota Supplier Relations Fixing the Suprima Chassis

Management Operations (MAN4504)

Bethesda University of California

Preview text

This case was prepared by MIT Sloan Professor Charles H. Fine and Senior Lecturer Donald Rosenfield, and Jamie Bonini, Vice President, Toyota Production System Support Center. This case was developed solely for educational purposes. Some names, data, and facts are fictional to protect confidentiality and improve pedagogical use. Therefore, this case may not be used as a source of primary data. Copyright © 2017, Charles H. Fine, Donald Rosenfield, Jamie Bonini. This work is licensed under the Creative Commons Attribution-Noncommercial-No Derivative Works 3 Unported License. To view a copy of this license visit creativecommons/licenses/by-nc-nd/3.0/ or send a letter to Creative Commons, 171 Second Street, Suite 300, San Francisco, California 94105, USA.

08- April 24, 2017

Toyota Supplier Relations: Fixing the Suprima Chassis

Charles H. Fine, Donald Rosenfield and Jamie Bonini

To say that Walt Bernstein, director of production control for Toyota Motor Manufacturing’s Macon, Georgia (TMMGA) operation, was frustrated in late 2004 was an understatement. “This situation is one of the most challenging I have faced in my 20 years with Toyota,” he admitted to David McDonald, the plant manager with ChassisCo, a Toyota supplier.

We’ve utilized all of our supplier support resources to solve the problems, but we still have not made adequate headway. Not only are the rear suspension cradles for the new Suprima crossover out of conformance, but the entire system for supplying and building this key subsystem for the Suprima vehicle chassis needs much more control and improvement. Your standard production rate is barely 60% of what it’s supposed to be, the parts you are sourcing are frequently nonconforming, and you need to improve your ability to track the problems you do find.

We’ve sent our engineering people, our project management people, our stamping experts, our welding experts, and our automation experts to your plant in Athens. After a year of making these rear suspension cradles, the rate of improvement is not sufficient. If we don’t turn this around, the entire vehicle program could be at risk. Quality could be impacted. We need to indentify and address any potential quality and conformance issues immediately.

Bernstein, responsible for managing relations with ChassisCo’s Athens, Georgia plant, was an expert in Toyota production principles. He was recognized throughout Toyota’s North American production network as one of its most seasoned leaders, with considerable expertise in welding, stamping, and body systems assembly. Bernstein had spent much of his career in Toyota manufacturing, often

Charles H. Fine, Donald Rosenfield and Jamie Bonini

working to improve the performance of suppliers who shipped parts and subsystems to Toyota’s assembly plants.

ChassisCo was a large international automotive supplier that provided a wide range of automotive systems and served many of the largest vehicle producers in the world. ChassisCo’s Athens plant was a 120,000 square foot facility dedicated to welding rear suspension cradles for one customer and one product: Toyota’s Suprima crossover vehicle. The Athens plant’s 350+ person workforce turned out approximately 200,000 rear suspension cradles per year, with 27 shipments per day leaving the plant.

“We’re working as hard as we can,” replied McDonald, ChassisCo’s plant manager.

As you know, we are doing much more on this model compared to what we did on the 1997 Suprima model. Taking Toyota’s lead, we have increased the automation in our plant dramatically. The number of robots has gone from 13 to 102 and the amount of welding on each rear suspension cradle has doubled from the previous model. We have taken responsibility for the development and supply of virtually every one of the 85 parts in the Suprima rear suspension cradle, and we aggressively worked the prices on second tier parts supply to meet the extremely aggressive target price demanded by Toyota. We’ve doubled the amount of value-added work content but are only utilizing about half the factory footprint we had before. We’ve reduced our production cycle times, and we’ve added a second Toyota plant that we service from our factory.

Furthermore, our quality staff has grown from 18 to 90 people, we’ve added two warehouses to store the incoming parts for the Suprima rear suspension cradle, we installed all of the automated equipment specified by Toyota’s engineers, and my staff and I are working 12 hours a day, seven days a week. What more do you want me to do?

“Well, it’s November 2004,” replied Bernstein. “We’ve been in production for 14 months and although there have been process changes and improvements, there are still major quality concerns. We need to take action.”

The Toyota Production System and Just-in-Time

Toyota’s Suprima crossover vehicle was built by Toyota’s vast TMMGA automotive assembly plant primarily for sale in the North American market. The plant had won numerous quality awards over the years and was considered to be one of the best automotive assembly plants in the hyper- competitive North American automotive market. In addition to opening TMMGA in the mid-1990s, Toyota had built a significant network of automotive factories in North America, and was expected to have a total of eight assembly plants and five engine plants by 2007.

Through the latter part of the 20th century, Toyota posted an enviable record of growth, profits, and customer satisfaction. Its market valuation of over $200 billion illustrated how operational excellence

Charles H. Fine, Donald Rosenfield and Jamie Bonini

inventory back to their suppliers. But this approach failed to capture the benefits of the systematic use of JIT for the entire supply chain.

Thus, JIT, and the TPS system that grew out of it, was not just a system for managing a factory; rather, its reach extended throughout the entire automotive value chain. The bedrock principles of JIT and TPS were continuous improvement and respect for people. Toyota made every effort to treat all of its stakeholders — employees, suppliers, customers, dealers, and shareholders — with respect. Relationships of mutual respect encouraged stakeholders to feel loyalty to the Toyota enterprise, which, in turn, motivated them to contribute to the continuous improvement of the enterprise. This intensive collective and creative effort aimed at continuous improvement generated superior performance highlighted by Toyota’s lower costs, superior quality, higher sales, and faster product development. Toyota took the fruits of this high performance and reinvested it across the stakeholder body. Employees, suppliers, dealers, and shareholders all received a surplus of value from their interactions with Toyota, further encouraging them to invest in greater enterprise improvement.

There was a second important principle of JIT that the inventory-centric view did not capture. JIT created conditions that enabled inventory reduction, including the reduction of waste and variability in demand and supply (for example, making sure that production steps were consistent, so that little inventory was required for protection against uncertainty).

Most importantly, in order to reduce waste and variability, JIT was about problem solving and being able to adapt to changing conditions. In order to address the wide array of variables that manufacturing companies dealt with, such as changing market demands, process reliability, adapting processes to new market conditions, evolving product design, changing suppliers, and giving suppliers new responsibilities, the system had to be able to solve problems and adapt.

Problem solving capabilities were particularly important for new locations. As TPS was implemented at a new location there were frequent routine challenges such as machine reliability or inconsistency, or particular types of defects that might show up periodically. These might be discovered though checklists and standard procedures. But then there were more significant challenges such as major gaps in quality or output or yield. Depending on the degree of the challenge and the skill level of the supplier, Toyota might suggest different levels of support for the supplier. These would involve a much higher level of collaboration. A supplier with relatively advanced TPS skill might very easily have the problem solving skills for routine problems, but without advanced skills, a major challenge could lead to more significant problems.

Toyota approached all members of its value chain, including suppliers, as long-term partners. This was the best way to develop problem-solving capabilities and the process capabilities that were required. Toyota selected suppliers carefully, looking for willingness to adapt just as much as for their technological capabilities. Once chosen, Toyota invested in a supplier organization’s education in TPS and capabilities wherever needed, whether it was in manufacturing, product design, or managing

Charles H. Fine, Donald Rosenfield and Jamie Bonini

its own supply chains. It placed high value on frequent and open communications and expected suppliers to alert Toyota personnel to problems very quickly so corrective action could be taken. Toyota encouraged a supplier’s people to get to know its people. The company expected suppliers to give it low prices because they had low costs, not because they were willing to lose money by doing business with Toyota.

For some companies, adopting TPS required simultaneous changes to many parts of the organization, a level of change that some would find hard to tolerate. Such change typically had to happen gradually, requiring great patience. Nevertheless, many companies had seen great leaps in improvement by creating better systems through learning about TPS and customizing the ideas behind it to fit their own situations. Not willing to become complacent, Toyota continued to improve and maintain a competitive edge from its use and improvement of TPS.

Some observers believed that if Toyota were run with a short term, shareholder value maximization mentality the company could squeeze more surplus out of employees, suppliers, and dealers so as to accrue more short-term profits for shareholders. Such an act, however, might be likened to “killing the goose that lays the golden egg.” Toyota stakeholders put much effort into building “golden eggs” for the Toyota enterprise exactly because they were confident that Toyota would continue to treat them well. Continuous improvement and respect for people were mutually reinforcing pillars of what was called “The Toyota Way.”

The 1997 Suprima Launch

The beginnings of Toyota’s relationship with ChassisCo had all the hallmarks of classic Toyota relationship building. In 1993, when planning for the launch of a new crossover vehicle in North America, Toyota thought long and hard before deciding to outsource the rear suspension cradle assembly to a North American supplier. Building rear suspension cradles was a difficult process; it required heavy parts, was technically complex and physically challenging, and was resource intensive. In Japan, Toyota built all of its rear suspension cradles internally. However, the TMMGA assembly plant, where the new Suprima would be built, was already space constrained. Furthermore, Toyota’s growth and globalization strategy required the development of a strong network of suppliers across all markets where the company had a significant presence. Toyota did not want to be vertically integrated and preferred to leverage its supply base with a supplier relations model that was robust and efficient.

After considering three suppliers, Toyota chose ChassisCo to make the Suprima rear suspension cradles. ChassisCo, which had built rear suspension cradles for Detroit’s “Big Three,” 1 agreed to build a greenfield site to support TMMGA production in Athens, Georgia, less that two hours away from the TMMGA plant. ( Exhibits 2 and 3 provide organizational charts showing some of the relevant Toyota and ChassisCo groups involved in the Suprima program. Exhibit 4 provides some of

1 The Big Three are General Motors, Ford and Chrysler.

Charles H. Fine, Donald Rosenfield and Jamie Bonini

Richard Roberts, who had been the Athens plant quality manager for ChassisCo, recalled feeling confident after the 1997 Suprima launch: “We thought we were pretty good. We were doing material flow kaizens (improvement projects), we had established a team leader system, and we had a strong training system for incoming welders. Of course, we did run into quality problems from time to time, but each time we were able to get things back under control. We were very proud of the awards we won during that time period.”

The Responsa Success

Subsequent to the 1997 Suprima launch, ChassisCo turned its attention to another Toyota program that once again called for rear suspension cradles for the new 1999 crossover vehicle, the Responsa. For the Responsa launch, ChassisCo opened a new plant in St. Louis, Missouri. For this new model, manufacturing involved considerably more automation. There were now 50 robots added to the line, which posed a new level of challenge for ChassiCo, and potentially increased the need for tuning. However, the rear suspension cradle production ramp-up was gradual and went quite smoothly. For the Responsa launch, the parts were initially sourced from Toyota in Japan, but were subsequently transferred to ChassisCo and, from there, to North American suppliers.

The success of the Responsa launch at ChassisCo’s St. Louis plant, including the local sourcing of its rear suspension cradle parts and dies, led Toyota planners to believe that the 2003 Suprima launch would constitute a natural progression of increasing capability and responsibility for ChassisCo. Toyota agreed to give ChassisCo ownership of project management for the components parts during launch with Toyota providing technological support.

The 2003 Suprima

Learning Curves

While Toyota felt confident in giving ChassisCo project management responsibility for the 2003 Suprima, some within the Toyota organization had concerns. As Carol Kinsley, who worked in TMMGA production control at the time, explained, “Although the Toyota engineers in Japan planned to design all the parts and equipment for the new line that would be required, they decided to let ChassisCo do all the parts sourcing and incoming logistics and inventory management. We knew the complexity facing Athens would be much higher for the new model.” TMMGA’s Lucy Martinez concurred:

ChassisCo had been asking for several years to supply the parts as well as do the rear suspension cradle assembly. We knew this would be a big leap for them and, frankly, some of us at TMMGA were quite surprised when Toyota approved this for the new model. The new rear suspension cradle for the 2003 Suprima was a lot more complex than the cradle for the earlier model and it had far more parts.

Charles H. Fine, Donald Rosenfield and Jamie Bonini

For the 2003 Suprima rear suspension cradle, stamped metal parts arrived by the truckload from Tier II suppliers to a ChassisCo warehouse managed by a third party logistics company. After being unloaded and put onto small “totes,” materials were pulled into Athens’s parts receiving room several times a day. These parts then entered one of two main lines: either where the left and right “cradles” were assembled, or to feeder stations scattered around the plant, which built up subcomponents (with either welding or riveting) that eventually were fed into one of the two main lines. Exhibit 8 shows a simple diagram of the process flow at the Athens plant.

With the additional responsibilities, it became clear that ChassisCo would need to show capabilities in many areas such as sourcing and logistics, and project management. In general, they would require the full range of skills in TPS. In particular they would need to demonstrate the problem solving skills that were such a key part of TPS.

But it would soon become quite apparent that the problems in the Suprima were significant and that concerns of people such as Kinsley and Martinez were justified. As Kinsley stated,

For the new Suprima model, I assumed ChassisCo would have competence in project management and I treated them that way. Over time, I came to realize that they did not have this capacity. ChassisCo was responsible for all second tier parts sourcing and development, but they had no system for tracking parts. We created a parts tracking system for them once we observed this deficiency. Systemically, ChassisCo was not organized to respond to Toyota’s need for integrated project management. Their organization silos were very strong.

“ChassisCo did not have the project management skills they needed,” added Lucy Martinez. “They did not even have a stage gate process in place. Their people worked very hard, but without processes to support them, they struggled to respond to our requirements.”

According to Walt Bernstein, we “failed to recognize how much more [TMMGA] needed to do to make the ChassisCo Athens plant successful, particularly in the areas of quality certification and inventory management.

We just didn’t realize the extent of the gap between ChassisCo’s capabilities and what we were asking them to do. We took for granted that they could develop the supply for the second tier parts. By the time we actually went and visited those suppliers ourselves, and we saw how far behind they were, it was very late. Several months before the launch date, they knew they were in trouble and we knew we were in trouble.

Bernstein identified significant capability gaps in the parts and tool tuning processes. For the 2003 Suprima launch, Toyota production engineers in Japan had done the tuning work for a handful of the most critical parts, expecting the ChassisCo staff to do all the rest (total of 85 parts). However the

Charles H. Fine, Donald Rosenfield and Jamie Bonini

I even went to the Toyota engineers and asked them for some design relief. If they only would have let us change the attachment methods, it would have simplified the assembly process. But, the Toyota engineers were adamant that their new design, with many rivet attachments, was a lower cost process and that cost was paramount. Adding to this challenge was the fact that Toyota rotated the engineering team we had developed relations with. I guess they thought that we had progressed and we no longer needed their most seasoned engineering support.

Richard Roberts explained the challenges he faced as the Athens plant quality manager:

At the plant level, we did not have the capabilities or infrastructure to meet the requirements of the new launch but everyone on the Toyota side as well as the ChassisCo side was very slow to realize this. Toyota introduced us to the TIS — Technical Instruction Sheet — which specified for every part several pages of detailed technical requirements that we needed to work on with our parts suppliers. This was our first exposure to a TIS and we did not know enough about how to use it. We thought we could do it, but we couldn’t. Other ChassisCo plants that served other ChassisCo customers managed the wide range of activities that we were being asked to do. But, Toyota’s requirements were far more stringent. Our other customers seem to care primarily that the assembled rear suspension cradle meets specs. They don’t place nearly as stringent requirements on the individual parts.

The increased level of automation in the welding processes for the new Suprima compounded the challenges for the ChassisCo plant staff and operators. In the manual welding processes used for the 1997 Suprima cradles, a weld operator could visually inspect his work in real time, observing the contours of the two surfaces to be joined and continually adjusting the location of his weld gun and the amount of welding done to assure a quality weld. With the new automated welding robots used for the 2003 Suprima cradles, however, no such real time, closed loop feedback system existed. If a part was off spec by a small amount or a weld gun was out of alignment, the weld would just miss or imperfectly join the parts, requiring significant inspection and rework to identify and repair the defects. Additional resources would then be required to trace down the source of the defects and adjust the welding system and/or work with the part supplier to improve its part conformance. These resources did not exist in the Athens plant when the 2003 Suprima was launched.

According to Ben Berkner, ChassisCo’s vice president of business development, the required resources were not available for a number of reasons:

The aggressive target prices that Toyota set for the new rear suspension cradles compounded the project’s problems. ChassisCo erred in even trying to reach the price that was set. We needed more plant space, but decided to cram the new line into the very tight existing space to save money. To try to meet the target price, we accepted low bids from parts suppliers, but failed to realize the implications for parts quality and delivery frequency. We chose one Georgia supplier

Charles H. Fine, Donald Rosenfield and Jamie Bonini

that had never made structural auto parts, did not understand the durability required, and had only produced simple, lightweight parts for computers and automotive interiors. Late in the process we had to abandon that supplier and replace the dies it had planned to use. Compounding these problems, we made errors in cost estimation, dramatically underestimating our logistics costs. Perhaps our biggest mistake was that we did not communicate to Toyota that we did not think the price was realistic.

TMMGA’s Walt Bernstein spent the entire summer of 2003 traveling to ChassisCo suppliers in the Midwest trying to set up and debug the stamping processes for the parts to be sent to Athens. Core to the practice of TPS was genchi genbutsu , or “go to the source and see things yourself.” However, ChassisCo had not visited its suppliers. In fact, the company had a limited number of people skilled enough to effectively audit its suppliers and identify problems. TMMGA typically practiced “go and see” only at the first tier, and by the time Bernstein realized the extent of the problems and went on the second tier visits himself, the project was in deep trouble. “I knew we were in trouble when I heard Walt’s reports from the supplier visits,” recalled Carol Kinsley. “Toyota stringently follows a communications policy of ‘bad news first.’ We want to identify problems early in the process, but the problems in the second tier had not been made visible to us. We discovered them much too late. From the viewpoint of some on the Toyota side, this was a big blow to our relationship.”

The other big problem Bernstein uncovered was at ChassisCo’s Tulsa, Oklahoma plant:

That plant was supposed to make some of the largest and most complex stamped parts for the Suprima rear suspension cradle. The plant had provided similar parts for one Detroit automaker, but they added new capacity for our stampings. They had a myriad of problems with their die automation equipment. They underestimated the complexity of the job and had not allocated sufficient human resources to get the job done. They were not capable of meeting the required production rates at startup. By summer of 2003, we were in crisis mode. The problems were escalated to the top of ChassisCo’s corporate structure where they got attention, but ChassisCo did not have well-defined processes to fix the problems quickly.

The Launch

To the surprise of some, the Suprima launched on time in September of 2003, although the production rate out of Athens was barely 60% of the target. The launch proceeded despite the fact that the Athens plant had failed three times in August to pass the high volume production trial (HVPT) required by Toyota. This trial required that the Athens plant demonstrate that it could continuously deliver the required production volume at required quality levels for one continuous hour.

Two months after launch, Athens was producing rear suspension cradles that had been specified at two-thirds the production rate. Many of ChassisCo’s suppliers also were not producing at the required rates adding a significant amount of overtime and cost overrun into the process. Among other

Charles H. Fine, Donald Rosenfield and Jamie Bonini

Progress was quite elusive, however. Since the line output was so low due to defects and downtime, the Athens plant was averaging approximately four hours per day in overtime (over two shifts), plus many Saturdays throughout 2004. Some TMMGA personnel feared that burnout could take the plant into a downward spiral from which it could not recover. One TMMGA analyst prepared the chart in Exhibit 10 to illustrate the risk.

Another major frustration for TMMGA personnel was the Athens plant’s weak quality information system. Particularly troubling was the absence of a defect flowout control system. When a major defect was discovered on a rear suspension cradle in the Athens plant, TMMGA needed to know how many rear suspension cradles had this defect and which defective rear suspension cradles, if any, had flowed out of the Athens plant into TMMGA. “We absolutely do not want to be building vehicles with rear suspension cradles with known defects,” explained Ray McMasters, who had been a purchasing manager at Toyota in North America.

The problems reached a boiling point in the fall of 2004. TMMGA continued to put a lot of pressure on Athens for fixing the underlying problems and Athens was not able to respond at a level close to what was expected. “We can’t continue like this,” said David McDonald, Athens’s plant manager. “This plant is bleeding money. We’ve flooded the facility with workers and inventory to try to keep up, but we are not making headway fast enough. We are going to have to ask Toyota for a significant price increase to cover our added costs.”

“This is more than a cost issue,” replied Bernstein. “More importantly, it is a quality concern. We must fix the underlying problems.”

“I understand that’s the Toyota Way,” replied McDonald. “But I do not have the resources to do any more than what we’re doing.”

“I have to admit,” replied Bernstein. “Our resources on this project are taxed to the limit. TMMGA is not resourced to solve supplier problems with this much complexity. We have already devoted far more resources to the rear suspension cradle problems than to any other part of this vehicle program. As I said before, we need a breakthrough and we need to consider the critical next steps to address these issues immediately.”

What could Toyota do to address the situation? Was this a typical challenge that they could apply TPS to, or was some other type of approach needed? If so, what would that be?

Charles H. Fine, Donald Rosenfield and Jamie Bonini

Questions (please prepare answers to be discussed in class)

What are the main contributors (causes) of the crisis at ChassisCo’s Athens plant in late 2004 (14 months after SOP)? a. ChassisCo’s responsibility? b. Toyota’s responsibility?

Considering these causes: a. What are ChassisCo’s options for resolving the crisis? b. What would you do if you were in charge?

Considering these causes: c. What are Toyota’s options for resolving the crisis? d. What would you do if you were in charge?

Charles H. Fine, Donald Rosenfield and Jamie Bonini

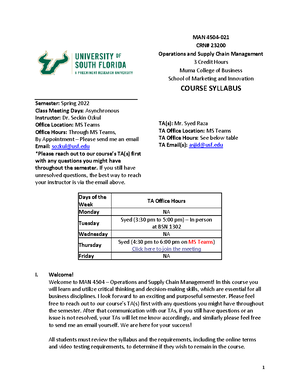

Exhibit 2 Toyota Organization Chart

Exhibit 3 ChassisCo Organization Chart, 2003

*other VP9s had similar org charts ** report thru SBU President to CEO

Toyota Japan

TMMGA

Toyota Eng. & Mfg.*

PC Purchasing Engineering Purchasing Quality

Structures Vice President**

VP

International*

VP USA

VP Canada* Director Purchasing

Director Sales Director Engr. Athens Plant Mgr St Plant Mgr

Program Mgr Quality Mgr

Charles H. Fine, Donald Rosenfield and Jamie Bonini

Exhibit 4 Timeline for Key Case Facts and Events

Exhibit 5 ChassisCo Suprima Cradle

Nov 2004; Bernstein seeks help

1993; Initial planning for first generation Suprima

1997; Launch of first generation Suprima

1999; Launch of the Toyota Responsa with ChassisCo rear suspension cradles

2000; Initial planning for second generation Suprima

Sept 2003; Launch of second generation Suprima

Charles H. Fine, Donald Rosenfield and Jamie Bonini

Exhibit 8 Suprima Rear Suspension Cradle Assembly Line: Original Layout for 2003 Launch

- 11

100- 1

- 8

- 9

Shipping

Paint

Charles H. Fine, Donald Rosenfield and Jamie Bonini

- Exhibit 9 Athens Internal Quality Defect Trends,

-

-

-

-

-

-

-

-

-

- 1, - # of Defect - - - - - - - - 1, - MAY # of Defect - JULY

Case Study Toyota Supplier Relations Fixing the Suprima Chassis

Course: Management Operations (MAN4504)

University: Bethesda University of California

- Discover more from: